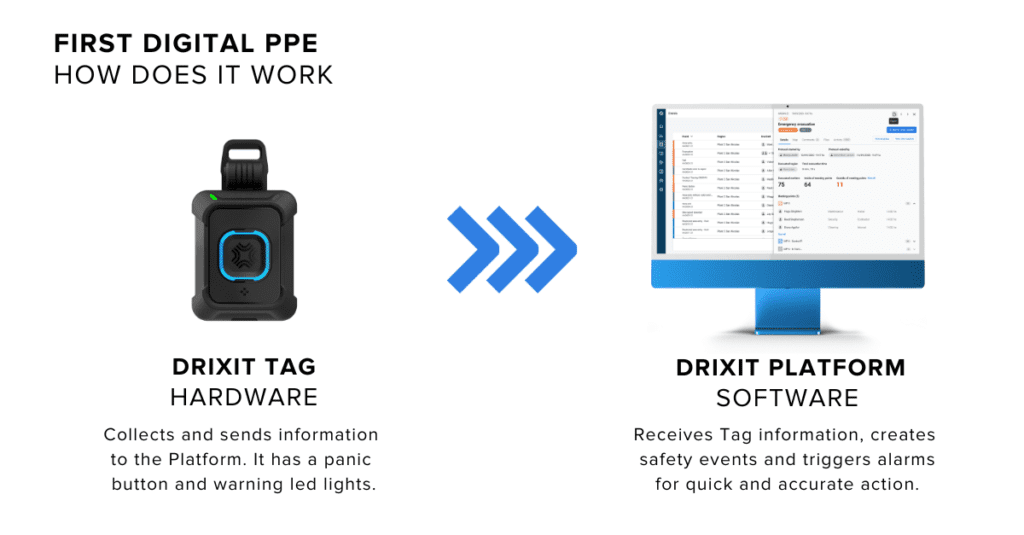

The Drixit Tag is an integral part of the first digital PPE (Personal Protective Equipment), together with the Drixit platform. Both make up a solution that allows to enhance the protection of industrial workers, thanks to the use of technology and the digitization of safety processes.

To begin to explain it concretely and briefly, which we will go into in more detail later, the Drixit Tag is a device used by the workers, it is the hardware of the solution. The Drixit platform, on the other hand, is the software that receives the information from the Drixit Tag, in real time, and is used by the security leaders and supervisors designated by the company.

With the information that the Drixit Tag sends, the platform detects previously configured actions and creates a security event. This safety event (e.g., entry into a risky area), issues an alert predefined by the user (e.g., triggering an SMS or notification to the supervisor). This allows safety leaders to be aware of worker safety, respond immediately to accidents and take proactive safety measures.

Some of the safety events that the digital EPP addresses have to do with Evacuation, First Aid, Hazardous Area Management, Contractor Management, Isolated Workers, Collision Prevention, among others. But let’s continue with the Drixit Tag, and everything there is to know about it.

Drixit Tag Specifications.

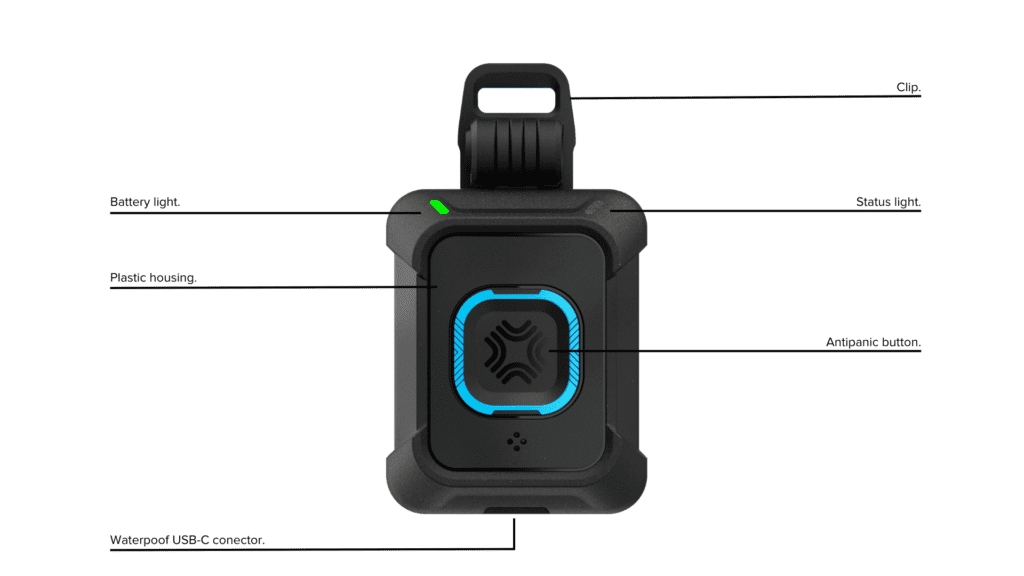

The Drixit Tag is a portable device designed to protect industrial workers in high-risk environments. It has a comfortable and ergonomic design, with a size of approximately 10 cm x 6 cm x 2 cm, and a weight of 100 grams. It has a clip that allows it to be attached to workers’ pockets, avoiding snagging or friction, in accordance with the safety standards of industrial plants.

Although it fits comfortably in the palm of the hand, it is compact and robust, and was developed to operate in the most demanding conditions of industrial environments. It is therefore waterproof, dustproof and certified for explosive atmospheres.

In addition, the Drixit Tag has a long-lasting internal battery, which allows it to operate for up to 25 hours without the need for a new charge (depending on the active functions of the device, with high-power GPS it can last up to 15 hours).

How does the Tag protect industrial workers?

As we briefly explained before, the Drixit Tag obtains data and sends it in real time to the Drixit platform. It does this because it has an infinite number of connectivity modes: LoRa, GNSS, UWB, WiFi and Bluetooth/BLE.

Sending information in real time allows the platform to detect:

- Workers immobile for a certain amount of time (preset by the user), such as operators who have suffered fainting, dizziness, heat stroke, heart attacks, cardiovascular accidents or any other accident.

- Work at height: The device detects and reports falls from a height of 1.2 meters or 4 feet and above.

- Authorized certificates:

- Entry, stay and exit from risky or unauthorized areas: this is especially useful for plants that have areas of high and/or low temperatures, confined spaces, flammable gases or any other condition that threatens the health or integrity of the worker.

- Collision prevention: The solution allows detecting the proximity between a pedestrian (Tag holder) and a vehicle equipped with the Drixit Spotter, sending real-time alerts to both devices to prevent the collision.

- Real-time detection of workers in the event of an emergency: when the Evacuation module is started in an emergency, the platform can detect the location of the missing workers and the status of the meeting points, facilitating the rescue work.

The Drixit Tag also has a panic button, which allows immediate help to be received in the event of an accident, whether it is one’s own or to help a colleague. It plays a fundamental role in safety, since the speed and agility of the response makes it possible to mitigate the consequences of unforeseeable accidents.

Try the Drixit Tag in your plant.

The implementation of digital PPE is an effective solution to improve industrial safety. It puts us at the forefront of safety, protecting our employees, preventing accidents effectively and responding quickly and efficiently when they happen. If you are interested, you can contact us here for a live test day, in your own operation plant.