Safety in industrial environments is a constant concern, especially when it comes to preventing collisions with forklifts. These vehicles represent a high risk in the workplace, and that is why solutions such as the Drixit Spotter are revolutionizing the industry by offering effective protection for operators.

State of accidents with forklifts in the industry.

To begin with, it is essential to understand the magnitude of the problem of forklift accidents in industry. According to a report by the World Labor Organization, approximately one in ten accidents in industrial settings involve forklifts.

Furthermore, it is estimated that each forklift has a 90% chance of being involved in some type of accident during its lifetime. These vehicles represent one of the major causes of accidents in factories and industrial plants, and it is estimated that 70% of accidents involving forklifts could be avoided.

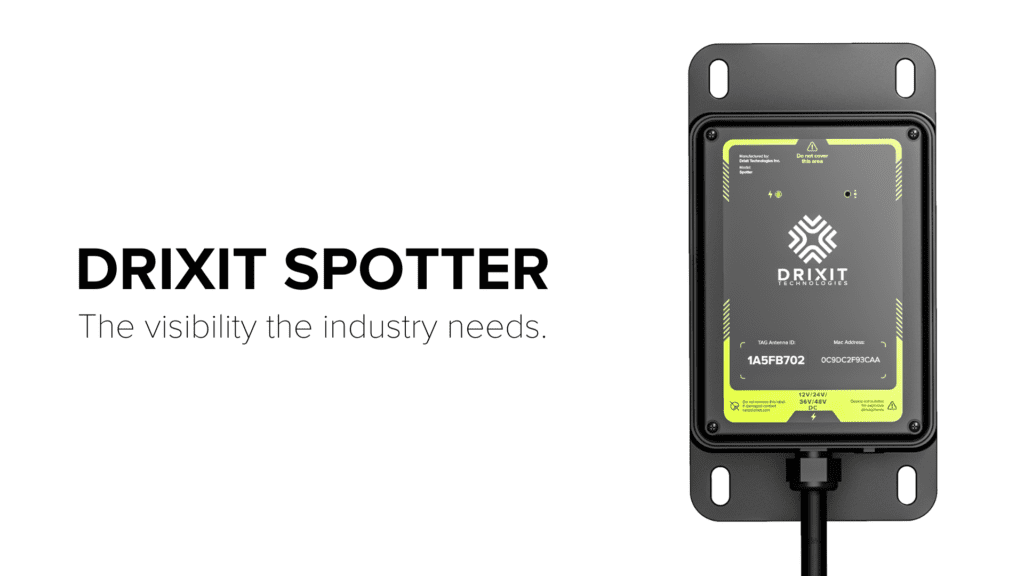

What is Drixit Spotter and how does it work.

Drixit Spotter is a collision detection and avoidance system designed specifically for industrial environments. It is comprised of a combination of advanced technology, sensors and communication devices that work together to ensure a safe working environment.

The system uses pedestrian/vehicle proximity detection as the basis for generating immediate audible and visual alerts when a risk of collision is detected. To do this, the Spotter must be installed in the vehicle and two safety areas (with configurable distances of 1, 2, 3, 5 meters, etc.) must be previously configured in the Drixit platform around it to detect proximity to pedestrians.

Pedestrians must also be using the Drixit Tag, a light and portable device designed by Drixit Technologies to prevent and mitigate industrial accidents. The interaction and identification between both devices is what prevents the collision.

Main functionalities.

The Drixit Spotter has a number of key functionalities that contribute to the prevention of collisions and the promotion of safety in the industrial environment:

- Proximity detection: The system uses high-precision sensors to monitor and detect the proximity between pedestrians (Tag users) and the vehicle, in real time.

- Audible and visual alerts: When a risk of collision is detected, the Drixit Spotter issues both an immediate audible and visual alert, based on yellow and red lights that are installed in view of the driver. The Drixit Tag worn by the pedestrian, in turn, vibrates to alert of the vehicle’s proximity. These alerts enable a quick and efficient reaction, avoiding collisions and reducing the risk of injury or property damage.

- Customized safety areas: The system offers the ability to configure up to two customized safety areas. This allows Drixit Spotter to be tailored to the specific needs of each work environment.

- Incident logging and analysis: All interactions between vehicles and pedestrians are recorded on the Drixit platform. This provides a detailed historical record of incidents, allowing subsequent analysis and identification of areas for improvement in terms of safety.

The Drixit Spotter has become an effective solution for preventing collisions in industrial environments. Thanks to its proximity detection capability and immediate alerts, the system provides operators and drivers with early warning of potential collisions.

At the same time, the incident logging and data analysis facilitated by Drixit Spotter contributes to continuous improvement of workplace safety by identifying recurring patterns and areas of risk.